Semi-trucks are not the best at saving fuel. We all know that, but how bad is it? Well, the typical semi-truck averages roughly 6 miles per gallon (mpg). This number will fluctuate depending upon the amount of freight a truck is carrying, the aerodynamics, whether it’s going uphill (sometimes getting 2mpg) or downhill (sometimes 20+mpg), etc. Believe it or not, the fuel savings have increased since the 1970s, but not by a significant margin. However, new development in technology and aerodynamics is enabling large fleets to make simple additions to their trucks, allowing them to save more fuel.

How does the aerodynamics work on a semi-truck?

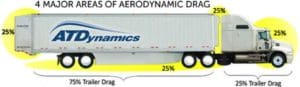

There are four major areas that affect the aerodynamic drag of a semi:

- The front of the tractor

- The gap between the trailer and the tractor

- The sides and underbody of the trailer

- The back of the trailer

Naturally, the methods used to make semi trucks more aerodynamic will address these four areas.

Fuel-efficient trucks will have the following in common:

Minimized gap between the trailer and the tractor

This is a fairly important aspect of a semi-truck’s aerodynamics, accounting for about 25% of drag. The gap between the tractor and the trailer creates a vortex, which causes friction. Fuel savings are reduced when the gap is larger because it creates more friction.

Trailer Skirts

Trailer skirts are placed underneath the trailer, between the trailer’s axles. This redirects the airflow and eliminates drag from the undercarriage. This helps save fuel by placing less strain on the drive train, making it more efficient at higher speeds.

Trailer Tail

TrailerTail is a new technology that reduces the drag caused by the rear end of the trailer. Large rectangular boxes are poor aerodynamic shape, therefore it’s not the best fuel efficient shape to pull down the highway. TrailerTail’s improves the rear drag of a trailer by redirecting airflow, which can improve fuel efficiency by 6%.

Aerodynamic Mud flaps

Some mud flaps are designed with aerodynamic benefits that reduce drag. Plus they make driving safer for others on the road since they catch debris that the wheels might kick up.

Wheel Covers

The wheels themselves can trap air as they spin, creating drag. Wheel covers can help reduce drag caused by a semi’s 18 wheels by closing air-trapping gaps and creating a more aerodynamic surface.

Rounded Corners

Finally, rounded corners on semi trucks further help reduce drag and improve aerodynamic performance. Studies conducted by NASA during the ‘70s and ‘80s confirm this, with tests indicating that rounding corners reduced drag by 54%. This also helped to reduce fuel consumption by up to 25%.

Advantages of More Aerodynamic Semi Trucks

More aerodynamic semi trucks are advantageous to anyone in the shipping industry, and their benefits can extend to their customers as well. The key benefits of streamlining semis include the following.

Reduced Drag

Reduced drag is the first benefit, and it leads into the other advantages described below. With less air resistance against the truck and trailer, the engine doesn’t have to work as hard, which is better in terms of both fuel consumption and the longevity of the vehicle’s components.

Reduced Fuel Consumption

With less mechanical work needed to overcome wind resistance, more aerodynamic designs for semis yield reduced fuel consumption. This means less revenue is spent on fuel over the course of a shipment, which can add up over long journeys. It could also lead to fewer refueling stops, which can help shipments arrive a little faster.

Less Wear on the Vehicle

Improved aerodynamic performance can also reduce the wear and tear on the vehicle and its components. The drive train and engine in particular can last longer with less resistance to overcome over the course of hundreds of long-distance journeys, especially those involving particularly heavy loads.

Lower Overall Costs

With reduced fuel consumption and less wear on the vehicle, there’s less overall expense needed to haul heavy loads and maintain the trucks. This can reduce overall costs for both the shipment company and their customers, and it can make hauling more profitable for truckers.

Trucking Is Also Getting Greener

Kraft Foods began using diesel-electric hybrid delivery trucks in 2009. Walmart recently redesigned the long-distance truck as we know it. The Walmart Advanced Vehicle Experience Concept Truck has a fuel-flexible, air-cooled microturbine-powered series hybrid electric drivetrain; a trailer made of carbon fiber (10 times stronger then steel an lighter than fiberglass) that saves around 4,000 pounds; and a streamlined style that provides 20% aerodynamic improvement and a 10% fuel reduction.

It’s not just the heavy hitters who are going green. Heavy Duty Trucking’s list of “Top 50 Green Fleets” includes lower tech solutions, which helped companies make the “Top 50” list, too. Celadon Trucking of Indianapolis, IN, invested in trailer side skirts, truck side skirts, cab extenders, aero bumpers, aero mirrors, roof caps, battery operated APUs, SmartWay-certified tires and more. Gordon Trucking (Pacific, WA) recycles all waste oil, coolant, batteries, metals, tires, and other items and reuses the fuel from filters removed at PM. FedEx Freight educated its drivers on fuel-efficient driving habits, like progressive shifting, cruise control and idle reduction.

These simple measures can have a huge impact. Verizon, which has over 35,000 on-road vehicles, saved more than 200,000 gallons of fuel in 2012 by just reducing idling. Unilever saved miles, too, by backhauling (using other companies’ trucks during their return legs, when they are typically empty). Their backhauling arrangement with partners in Hungary and China has reduced vehicle distances by 50,000 km, and saved the company 10% in distribution costs.

Frequently Asked Questions

What is a trailer tail on a semi truck?

A trailer tail is also called a boat tail and is used to improve fuel economy by making the trailer more aerodynamic.

What are the side skirts on semi trailers for?

Side skirts are used to reduce aerodynamic drag and turbulence that slow down semi-trailers and reduce gas mileage.

Why do semi trucks have flaps on the back?

How do semi trucks reduce drag?The flaps on the back of a truck are called rear tail fairings, and they can help reduce drag on the vehicle. They may also catch any gravel or debris tossed back by the vehicle, potentially saving the windshields of anyone following behind.

How do semi trucks reduce drag?

As described above, there are many ways semi trucks reduce drag. These methods include trailer skirts, tails, wheel covers, closing gaps, and rounding corners, to name a few.

Efficient Hauling for Your Load

If you need something hauled long distance, we can help you arrange for the most efficient shipment possible. Regardless of the size and weight of your particular load, we can manage the logistics of your shipment. Contact Next Exit to learn more.